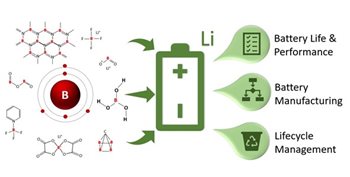

We’re excited to announce an SCIE-indexed peer-rereviewed journal, Batteries, recently published a new literature review on boron compounds in lithium-ion batteries by U.S. Borax’s Changlin (Allen) Zheng, Principal Advisor—Strategic and Technical Marketing.

Zheng’s paper includes a comprehensive review of prior studies on boron compounds in lithium-ion batteries. The boron-centric paper enables researchers and industry experts to easily understand outcomes of past studies, draw similarities to their own research, and facilitate new ideas.

For an industry experiencing rapid commercial growth, the paper covers topics critical to improving three major areas:

For an industry experiencing rapid commercial growth, the paper covers topics critical to improving three major areas:

- Battery life and performance

- Battery manufacturing

- Lifecycle management

Hopefully, this paper will enable more extensive use of boron in lithium batteries. Below are a few highlights:

Boron lithium compounds enhance a battery’s interfacial layer

Various studies included in the paper show boron lithium compounds are effective in assisting the formation and stability of the interfacial layer between the electrode and electrolytes. These boron compounds can be introduced through electrolyte additives or directly used as electrolyte.

Boron compounds provide diverse benefits to anodes

When boron compounds (boric acid) are directly applied to anodes, batteries experience diverse benefits such as improved graphitization and improved interfacial layer. Manufacturers can apply boric acid to anodes either through direct usage or anode upcycling.

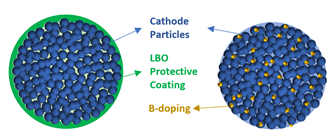

Cathode doping and coating improves cycling performance

The paper summarized two conventional approaches of using boric acid on cathodes—cathode doping and cathode coating.

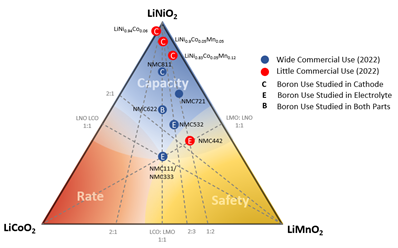

Boron compounds in cathodes system that are used in commercial application

Researchers are studying how boron compounds impact cathode systems in electric vehicles (EV)—some have been widely seen in current commercial applications. By using boron compounds on the cathode, EV manufacturers can improve cycling performance and structural stability.

Types of systems covered in the paper include:

- Nickel-cobalt-manganese-aluminium (NCMA)

- Nickel-manganese-cobalt (NMC)

- Nickel-cobalt-aluminum (NCA)

- Lithium-iron-phosphate (LFP)

Boron may maximize manufacturers’ efficiency. The paper explores how using boric acid is an effective approach in cathode washing for residual lithium compounds (RLCs).

Boron compounds to improve manufacturing

Battery Thermal Management Systems (BTMS) and separators

Boron nitride is a commonly studied chemical compound in BTMS and separators because of its unique combination of high thermal conductivity and high electrical insulation.

Need more information on boron in battery applications?

Read the article in Batteries, an MDPI publication. Or, for specific questions contact Allen directly.

Resources