For thousands of years, people have valued glass because it’s:

- Inexpensive to produce

- Easy to shape

- Transparent

But traditional glass formulations (sodium carbonate, limestone, and silica) lacked the durability needed for certain industrial applications.

That is, until one researcher made an important discovery: Using boron in glass formulations created a stronger, more durable material. This new type of glass—borosilicate glass—featured better heat and chemical resistance, an important quality for laboratory use. And, it had superior optical clarity.

The discovery of using boron in glass formulations launched an exciting period of innovation.

Borosilicate glass goes mainstream

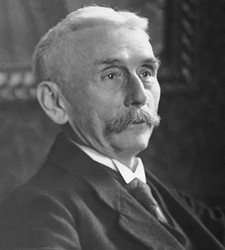

In the late 19th century, Otto Schott, an enterprising German scientist, had a vision: He wanted to make laboratory glass clearer and more durable.

In the late 19th century, Otto Schott, an enterprising German scientist, had a vision: He wanted to make laboratory glass clearer and more durable.

With help from physics professor Ernst Abbe, Schott began testing different additives in glass formulations. He found boron to be the most promising. Using boric acid, Schott developed the first borosilicate glass formulation, a breakthrough that several industries would quickly adopt.

Photo courtesy of SCHOTT AG, SCHOTT Corporate Image Database

Pharmaceutical glass

After Schott’s initial success, he partnered with Abbe and Carl Zeiss, a microscope producer, to form the Schott & Associates Glass Technology Laboratory. The company, now known as SCHOTT, developed a formulation suitable for pharmaceutical glass packaging.

For more than 111 years, the pharmaceutical industry has used this formulation to serve the needs of scientists and patients. Borosilicate glass also later enabled innovative products such as single-use syringes.

Railroad safety

Railroads became the next American industry to adopt borosilicate glass. In the 1900s, Corning Glass Works developed a new formulation to replace the existing glass in train track safety signals, which regularly shattered upon sharp temperature swings.

Cookware

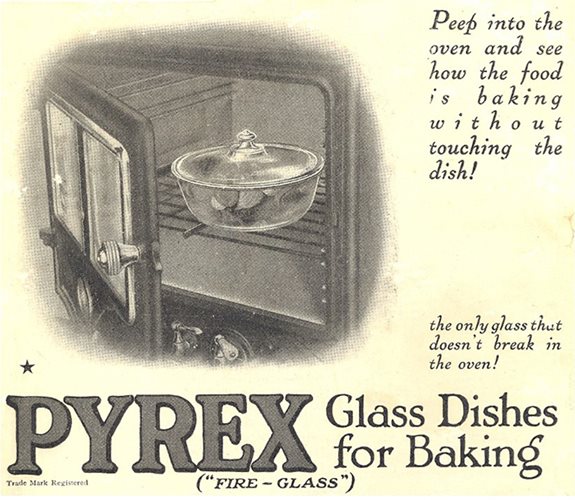

Photo courtesy of Corning Incorporated, Corporate Archives

Nearly a decade later, a Corning scientist brought a sample of the company’s borosilicate glass home to test its thermal expansion properties in a new way: Cooking. Again, the glass proved successful and glass ovenware, commonly known Pyrex®, was born.

Glass fiber

In the 1930s, U.S. scientists successfully developed a better process—using boron—to produce glass fibers on an industrial scale. The process involved forming a continuous filament by extruding multiple strands of glass through a bushing with tiny holes. These glass fibers were used in textiles, electrical work, and came in a resin-bonded form used in boat-hulls.

Mass production of glass fibers also coincided with another important new product: Fiberglass insulation, one of the largest uses for boron in glassmaking today.

Preparing for expansion

As more industries discovered the need for durable glass, it appeared borosilicate glass would continue its impressive expansion. Then World War II began, disrupting life and supply chains.

Once the war ended, borosilicate glass growth returned at an unprecedented pace—from cookware to car headlights to all forms of laboratory glass. And with high energy costs, energy-conserving products such as fiberglass insulation experienced significant growth.

Later in the 1990s, borosilicate glass extended into commercial and residential buildings with fire resistant glass. Because fire resistant glass has a low thermal expansion coefficient (high thermal shock resistance) it prolongs the critical escape time during fire emergencies.

In the 21st century, the booming LCD-TFT display industry expanded the need for boron in glass. In display applications, boron is used in substrate glass, color filter glass, and cover glass providing the needed thermal, dielectric, and mechanical properties.

For all these products and applications, companies turned to U.S. Borax as a trusted supplier and partner. We worked hard to advance the value of borosilicate glass, through product quality and collaboration partnership.

Boron in glass: Powering today and future’s needs

Glassmaking product and manufacturing innovation continues—and we remain at the forefront of extending boron’s value in the industry. With 150 years of production and innovation history, U.S. Borax supports the glass industry as both a reliable, refined borates supplier and a trusted research and development partner. We are committed to exploring collaboration opportunities with academic or industrial partners.

Products

While boron continuously plays an instrumental role in glass applications that have stood the test of time, there are exciting new products and applications that leverage boron in glass formulations:

- D-glass fiber for telecom applications

- Borophosphate glasses for photonic, optophotonic, or biomedical applications

- Boroaluminosilicate glass for chemical applications

- Lithium aluminoborate glass-ceramics for thermal applications

Manufacturing

On the process side, glass producers are searching for ways to improve sustainability. Borates can help glass manufacturers conserve energy by lowering the melting temperature required for production. That means less fuel is needed, and consequently, fewer carbon emissions.

Our team is continues research on how anhydrous borates improve glass manufacturing, including reducing volatility loss and improving productivity.

Need help with your borosilicate glass formulation?

Our technical experts are here for you. If you have questions on cost, quality, or need guidance on the right borate concentration and particle size for your borosilicate glass formulation, contact us.

Resources

Pyrex is a registered trademark of Corning Incorporated.