Across industries, manufacturers face pressure to make products lighter, stronger, more energy efficient, and sustainable.

Hollow glass microspheres (HGMs) are tiny spherical glass powders that offer a way to meet these demands because they have:

Originally a costly specialty material for aerospace, defense, and deep-sea applications, HGMs are now more affordable and available thanks to advances in production technology.

As with other glass types, refined borates are essential in HGM manufacturing—lowering melting temperatures, improving molten glass flow, and enhancing chemical stability.

What are hollow glass microspheres and how are they used?

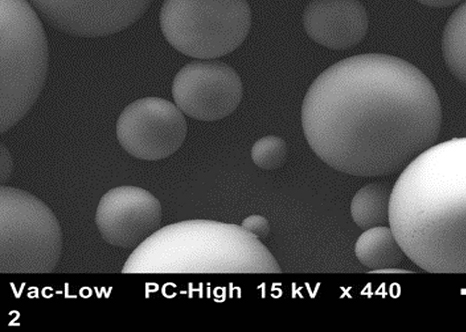

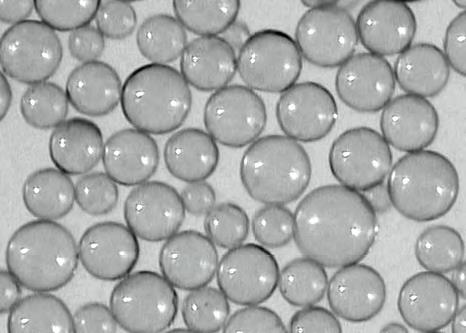

Hollow glass microspheres are extremely small spherical glass powders comprised of soda-lime borosilicate glass. They can be as small as a few microns to hundreds of microns in diameter. For comparison, you can fit dozens of HGMs across the width of a human hair.

Images taken of hollow glass microspheres under a microscope

The size and unique properties of HGMs make them suitable for use in a diverse range of products and industries.

Oil drilling and buoyancy modules

HGMs reduce weight, improve flotation, and withstand high pressures in deep sea environments.

Automotive and aerospace

Manufacturers seeking lighter parts without compromising strength can use HGMs to help improve fuel economy and reduce emissions.

Injection-molded components

Plastic parts that need greater durability without adding weight, can benefit from HGMs.

Electronics

The dielectric properties of HGMs help improve insulation in electronics and help devices run more efficiently and reliably.

How are hollow glass microspheres made?

There are two primary ways to make hollow glass microspheres:

- Solid-state glass powder

- Spray granulation

In the solid-state glass powder method, glass powder is heated until each particle puffs into a hollow sphere. This method produces HGMs that are fully glassy, with high strength and excellent chemical stability.

In spray granulation, liquid droplets containing glass materials are sprayed and dried into hollow beads.

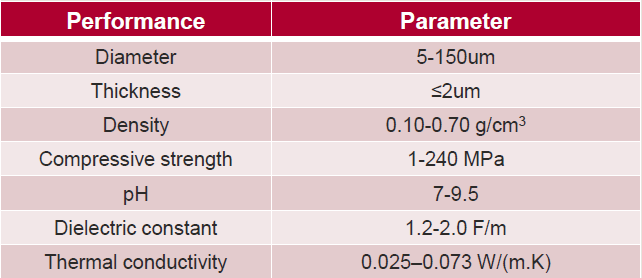

Typical HGM parameters

Borates in HGM manufacturing

Because HGMs are a type of borosilicate glass, borates serve the same network forming and flux role in the solid-state powder process as they do in other glass manufacturing processes.

When it comes to sourcing boron for HGM production, it’s important to look for a refined product to ensure no impurities are introduced in the glass batch. Refined borates also offer more consistent particle sizing, which results in a more uniform glass melt.

U.S. Borax products—Neobor®, Dehybor®, and Optibor®—are reliable boron sources for HGM. For many manufacturers, using an anhydrous borax product such as Dehybor offers the most advantages as it supplies both sodium and boron, significantly reduces energy consumption, and minimizes emissions.

U.S. Borax: A trusted glass industry partner

For decades, U.S. Borax experts have closely collaborated with glass manufacturers to improve efficiency, reach environmental goals, and ensure borosilicate glass formulations result in high-quality products.

If you produce HGMs, contact our technical team for questions related to boron sourcing.

Resources