Life as a miner in the early days of borate mining resembled what most people envision when they imagine the Wild West: Rugged and arduous.

Miners faced primitive living conditions, used rudimentary equipment, and logged long working hours filled with strenuous manual labor.

Miners faced primitive living conditions, used rudimentary equipment, and logged long working hours filled with strenuous manual labor.

Today, the lives of those working in our mine look much different. From more advanced technology to better living conditions to innovations in transportation—mining is safer than ever before.

Because our miners worked hard to establish a solid foundation for our operations, U.S. Borax continues to be a leader in the supply and science of borates. And, those pioneers paved the way for current and future generations.

Read more about U.S. Borax history

The early life of U.S. Borax and our miners

Francis “Borax” Smith first discovered a rich boron deposit in the Nevada desert in 1872, setting a course for the borate mining boom.

Back then, flour cost roughly 4 cents per pound, eggs were about 28 cents a dozen, and you could purchase coffee for 12 cents per pound. Many modern products such as the telephone, vacuum cleaner, and radio hadn’t been invented.

The average life expectancy in the U.S. was less than 50 years. For miners, who faced dangerous working conditions, life expectancy could be even shorter.

Dangerous work

In the early days, much of borate mining activity in the Western region of the United States took place underground.

Unlike today, the early, small claims infrastructure was often hastily set up with little care taken for worker safety. Risks came in all shapes and sizes from dark working conditions to explosions and mine collapse.

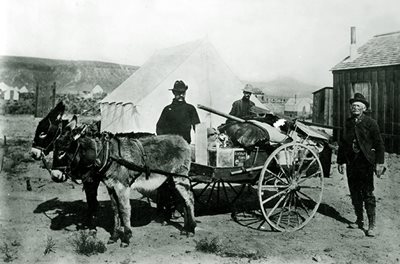

Taxing transportation

Even work above ground—once the material was removed from the mine—wasn’t easy for these mining pioneers. Many of the first borate deposits were discovered in remote locations in the greater Mojave Desert region.

Transporting borates required a team of 20 mules—famously known later for the advertising campaigns promoting 20 Mule Team® Borax™ laundry soap—in specially designed heavy-duty wagons. Crossing the desert meant battling extreme heat—with little support between the supply camps along the route.

Borate mining camp conditions

By the late 1880s, many of the borate sources in the greater Death Valley region were controlled by Smith’s newly formed Pacific Coast Borax Company (later known as U.S. Borax). In 1888, Smith built a mine that he named “Borate” about 10 miles from the nearest railroad.

By the late 1880s, many of the borate sources in the greater Death Valley region were controlled by Smith’s newly formed Pacific Coast Borax Company (later known as U.S. Borax). In 1888, Smith built a mine that he named “Borate” about 10 miles from the nearest railroad.

The mining camp featured a bunkhouse where the all-male workforce slept, a recreational center, and a small reading room. Miners ate three cooked meals a day and worked seven days per week. The remote location had extremely limited entertainment options.

Work at the mine was intense and physical. To extract bauxite ore from the underground mine and load it into an above ground ore car, a gas engine hoisted the ore up from the mining shaft in a 50-gallon whisky barrel. When it reached the surface, men waiting above had the taxing task of manually lifting the heavy boulder-like objects into the ore cars for transportation.

Modern borate mining life

Through the decades, key enhancements to operations, transportation, and living conditions improved miners’ lives.

Through the decades, key enhancements to operations, transportation, and living conditions improved miners’ lives.

The Industrial Revolution introduced machinery and automated processes to replace manual, labor-intensive ones. And, converting underground mining operations to a surface mine in 1957 unlocked more possibilities to transform efficiency.

Many of the early methods for extraction and transportation, including the 20 mule teams, have been replaced with modern equipment such as the Terex MT4400 Rock Truck. This impressive 16-cylinder, 2,500 horsepower truck is 45 feet long, 26 feet wide, and 24 feet tall.

Living conditions

Basic, yet fundamental, aspects of living conditions changed for miners as the western United States population grew—and amenities grew with it.

Looking at a modern miner’s life today, it’s almost hard to imagine miners used to live in tents. Now, our miners—both men and women—don’t have to even live on-site or work a grueling long schedule. Even though our operations are 24/7, employees work standard shifts, enjoy benefits, and have opportunities to advance within the organization.

Many career opportunities that exist now didn’t back then. U.S. Borax offers highly specialized positions such as engineers, electricians, mechanics, and haul-truck operators. And, we support our employees with robust training to ensure they are working safely and efficiently.

Despite all the change we’ve seen at U.S. Borax in last 150 years, one thing hasn’t changed: Our commitment to producing materials essential to human progress.

Resources