Staying in business for more than a century and a half isn’t easy. Only companies who openly embrace and adapt to change can survive. This year, we’re excited to join that exclusive list as U.S. Borax celebrates 150 years of borate mining operations.

During our time in business, we’ve seen drastic changes that have impacted every corner of our lives. The world—and the mining industry—today looks much different than at the time of our humble beginnings. So, what’s been the secret to U.S. Borax’s longevity?

Borax at the beginning

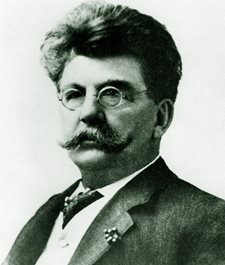

In the late 1800s, borate deposits were discovered in Nevada and California. Our founder, Francis “Borax” Smith, led the way by consolidating sources and growing market demand for borax.

The first mine

At the time, borate deposits were in remote locations. Without railways, roads, or even trails, borates needed to be hauled 165 miles across the Mojave Desert. Enter the infamous 20 mule team to pull wagons on the treacherous journey.

In 1888, Smith built a mine that he named “Borate” and it soon became a primary source of borax in the United States. Borate was only 10 miles away from a railroad—closer to a railroad than any borax deposit discovered at the time. The location proved to be a huge advantage as transportation was a major concern.

Mining continued at Borate until 1907 when it became too difficult and costly to extract material. The Pacific Coast Borax Company—the original name of Smith’s company, which later became U.S. Borax—then moved its mining operations to a new deposit east of Death Valley.

The move to Boron

In 1925, drillers made a monumental discovery: A major borate deposit in southern California, the site for what is now known as the town of Boron. Boron’s location made it a prime spot to find borates. A main line railroad was only three miles away, making the new ore more cost-efficient to mine and easier to transport.

In 1925, drillers made a monumental discovery: A major borate deposit in southern California, the site for what is now known as the town of Boron. Boron’s location made it a prime spot to find borates. A main line railroad was only three miles away, making the new ore more cost-efficient to mine and easier to transport.

Two years after the discovery, we built the first underground mine, establishing Boron as our principal location.

Modernizing boron mining operations

In 1957, our modern operations began to take shape as we converted the underground mine in Boron into an open pit mine. An extensive refining facility was built to accompany the updated mine.

Converting the mine transformed both safety and boron mining efficiency resulting in:

- Easier extraction

- Faster transportation

- Less equipment required

- Elimination of mine cave-in accidents

- More space for operation

Over the coming decades, new technology that suited open pit mine operations advanced efficiency even more.

For instance, consider transportation. At our Boron operations today, you’ll see modern equipment including our massive haul trucks as large as houses.

In the 1800s, it used to take one week for the 20 mule teams to haul 20 tons of ore across the desert to make one product. Now, it takes less than one hour to transport 270 tons of materials to make 16 products.

Looking ahead: U.S. Borax continues to innovate

Today, we’re still a leader in borate mining and development. We produce a third of the world’s supply of refined borate products. Our business spans the globe and we now manage the largest open pit mine in California.

And, we’re still finding ways to innovate and maximize value. In 2020, we safely completed a progressive closure of a processing plant within our operations—while work continued around it. Using advanced technology to ensure safety, we removed the structure and reclaimed space that can unlock new value for our operations.

Resources